Modular Buildings

Truck Loading Station Shelter

6′ x 12′ Interlocking Galvanized Sheet Metal Truck Loading Station Shelter with Shed Roof, Entry Door, Fixed Windows and Roof Mounted Lifting Lugs

This truck loading station shelter acts as a clearing house at the security gate entry of a refinery’s product delivery truck loading depot. While compact, it features an entry door, multiple viewing windows and sufficient space at the rear for a security guard’s truck depot computer terminal and work station. One special feature the client requested for this truck loading station shelter was top lift provisions, due to the lack of a forklift large enough to handle this structure. Upon arrival, the truck loading station shelter was quickly unshackled, off-loaded and swung into position using a cherry picker. The provision for top mount lifting eyes was designed in a manner to allow their removal, and an interior liner and white polyurethane finish for this truck loading station shelter completed this project.

This Truck Loading Station is installed at a refinery depot’s security gate entrance to receive and release delivery tanker trucks. The shelter features several strategically located viewing windows, a front door, an interior liner and special top-lift provisions. In addition, the shelter features an insulated steel deck base with a slip-resistant floor finish.

From the rear wall, the interior of this shelter may seem narrow, but is actually ideal for a single occupant to a building that serves as much as a security guard shack as a truck loading depot station office. From his desk, the security guard can easily look left or right to view in-bound and out-bound truck traffic.

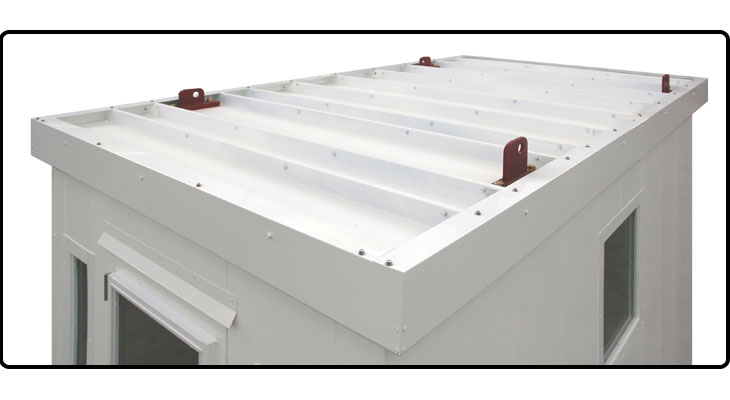

This unique top-side view of the Truck Loading Station reveals the critical position of the four top lift lugs. The lugs were secured to a metal framework which was seal welded to the base inside the wall cavities, thus transferring the lifting load from the lugs to the base.

A close up of one lifting lug demonstrates the serious nature of this provision. To ensure absolute stability during the off-loading process, each lug was constructed from two heavy steel plates that were seal-welded and primer painted, to ensure they would last a lifetime, even if the shelter is repositioned in the future.