Industry Specialties

Oil and Natural Gas

Analyzer Equipment Enclosure

This 10’8”W x 12’L x 8’H Analyzer Shelter housed the gas analytical equipment at a refinery in Long Beach, California. For this application, Parkline’s customer requested a “Material Only” package that included a 24-gauge wall system with an S-Style sloped roof, a door with a 24” x 30” viewing window, two 36” x 36” horizontal sliding windows for the side walls of the building, gutters, downspouts and the turbine vents on the roof. Parkline’s standard Desert Tan was chosen for the wall coating while the trim was requested in our standard Roman Bronze. All materials were professionally packaged and delivered to the site, where the building was then constructed by the end-users subcontractor. Design of this structure included compliance with all applicable IBC and IECC code requirements as well as adherence to local California codes, including the roof coating to meet Title 24.

Compressor Building

Site erection of this 32’Wx 60’L x 16;’H Compressor building was arranged by a Parkline dealer in Wisconsin for a natural gas company. Key features of this building installation included a large 12’ x 12’ roll up door, front and rear louvers for the ventilation of combustible air, a gable roof system with gutters and downspouts and two 3’ x 7’ personnel doors. Once installation of the building was completed, the client installed the utilities and a GPS antenna.

Electrical Control Building

Erected on a deck plated, tube-skid base for placement on a platform at a petroleum barge unloading facility in Nashville, TN. This 8’W x 8’L control building featured a sloped roof, gutters and downspouts, 3’ x 3’ sliding windows on each wall and a 3’ x 7’ personnel door. The stair and stilt materials were shipped to site for union erection of the platform and the factory assembled building was then shipped to the installation location and top-lifted into place. In addition, Parkline completed the installation of a basic utilities package and constructed the base with an extension to provide a walkway with the necessary safety handrail. The design and construction of this control building was done in compliance with all applicable code requirements.

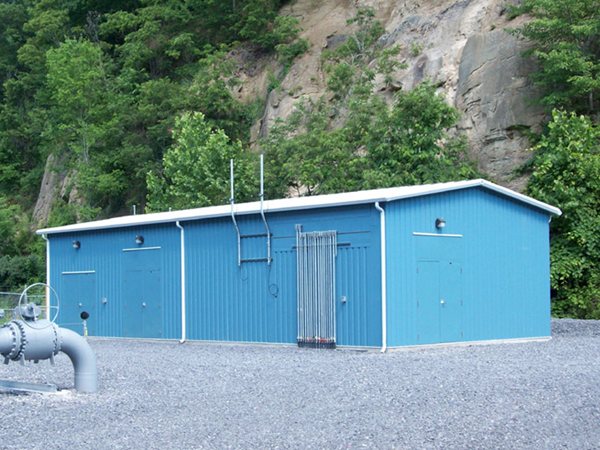

Electrical Control House

Constructed on-site by Parkline Field Services, this electrical control house was installed at a natural gas pumping station in Pennsylvania. Once completed the building provided a weather-tight cover for all Switchgear, MCC (Motor Control Centers), and the other electronic equipment required to run the station. This 28’W x 50’L x 12’H, twilight blue building was constructed of 24-gauge fluted wall panels and incorporated removable transoms, bulkheads for conduit entry, gutters, downspouts, a 6’ x 7’ double door and two 3’ x 7’ single personnel doors. Another key feature of this building is the AL-Style gable roof to accommodate the snow loads common to the state. Once all construction of the building was completed, the client arranged for all equipment integration. This control house was designed and constructed in accordance with the applicable IBC and IECC code requirements.

Equipment Storage Building

Parkline’s client ordered a materials-only package and then site erected this 12’W x 24’L x 10’H equipment storage building at a gas refinery in Kentucky. The materials package included all of the hardware necessary for building assembly, including the two 8’ x 8’ overhead doors, a 3’ x 7’ single door with a 24” x 30” viewing window pre-installed and a gutter and downspout system to control water runoff. To match the surrounding structures, the client ordered this building in our standard Twilight Blue.

Inside Electrical

Parkline supplied all of the Motor controls and the UPS systems for five identical MCC buildings that were constructed and fully integrated in our facility and shipped to their installation sites for a gas pipeline in Pennsylvania. In addition, Parkline’s integration team installed the VFD and the control panels into the 13’4” W x 32’ L building and designed the building with a 10’ Interior ceiling height to accommodate the gear and the ceiling mounted cable tray. Each building base included bottom lifting lugs and floor cutouts under the equipment for bottom access as well as additional floor cutouts to allow for future expansion. Constructed of 18-gauge shell gray exterior wall panels with a white interior liner, additional features included two 3070 personnel doors with windows, a removable transom to allow for placement of the gear, fully installed HVAC systems and a non-skid floor coating. All IBC and IECC code requirements were incorporated into the design and construction of these buildings.

Measurement and Regulation Enclosure 1

This 24’W x 60’L x 11’H measurementation building was purchased for a Municipal Township in New Jersey who requested the custom faux-brick façade with special brown trim. Parkline constructed the 4-piece modular building at the facilities of the contracted measurementation company who then integrated the building with the required hazardous location rated electrical components required to measure and regulate gas distribution. Once integration was complete, Parkline then coordinated with a union contractor to field reassemble the structure at the final installation site. Key features of the structure include gland plates, gutters, downspouts, an AL-style gable roof design, four pairs of 6’ x 7’ double doors and two 3’ x 7’ single personnel doors.

Measurement and Regulation Enclosure 2

Parkline’s dealer arranged for the on-site construction of this measurementation and regulation building in Allentown, PA. The 16’W x 20’L x 8’H building application was essential to enclosing a meter run and the associated equipment required for gas measurement and regulation at this site. Some key features of this building included the AL-style gable roof with a ridge vent, manual ventilation louvers to allow for the required 6 fresh-air exchanges per hour, a split gland plate for penetration of the pipe through the wall system, a 3’ x 7’ door, splash trim and a desert tan finish coat for the building.

Measurement and Regulation Enclosure 3

One of Parkline’s dealers arranged for the site erection of this 16’W x 24’L x 12’H measurementation building and the 4’W x 8’L x 8’H telemetry building installed next to it. Once the pad and piping layout were completed by the client, the erector constructed the buildings around the equipment, including the gland plates that allowed for leak-proof pipe penetrations through the wall system. Though both buildings were arctic white and featured an AL-style peaked roof system, the wall system for the larger measurementation building was constructed with flat 18 gauge interlocking galvanized panels and the smaller telemetry building was constructed with fluted 24 gauge interlocking galvanized panels to reduce overall project cost. A custom feature of the measurementation building was the acoustic rated wall and ceiling system, designed to reduce noise emissions to 49 decibels in order to be in compliance with code restrictions in Redding, PA due to the close proximity of the public tennis courts. Other features include 3’ x 7’ personnel doors, 6’ x 7’ equipment doors, acoustic rated louvers, gutters, downspouts and a ridge vent on the telemetry building.

Measurement and Regulation Enclosure 4

Installed in New Jersey, this 12’W x 16’L x 8’H Roman Bronze building with Desert Tan trim was assembled on-site at the customers facility by local union labor. The materials supplied for this building included multiple gland plates to allow for the pipe penetrations needed for this measurementation and regulation application. Featuring an AL-style gabled roof with ridge vent, a 3’ x 7’ personnel door the flexibility of Parkline’s materials only package allowed the client to customize the building to suit the environment and conditions specific to its installation. This building was designed and constructed in accordance with all applicable IBC code requirements.

Measurement and Regulation Enclosure 5

Parkline erected this 12’W x 16’L x 8’H measurement and control building on a customer supplied skid in Oklahoma before it shipped to its final destination. The finished building featured double doors on both sides and each door featured a viewing window and ventilation louver to allow for air flow inside the structure. Constructed of 24-gauge wall panels with gutters and downspouts for rain water run-off, the gable roofed building erection also included unistrut to allow for the mounting of the exterior light as shown in this photo. Once erection was complete, the building gland plates were installed around the pipe entrances to form a leak proof seal. All applicable IBC building codes were implemented into the design and construction of this equipment protection building.

Measurement and Regulation Enclosure 6

Site erected at a popular motorcycle plant in Pennsylvania this 16’W x 24’L x 8’H building was installed to enclose the measurementation and regulation equipment needed for natural gas distribution to the factory. This shell grey building featured 24-gauge wall panels with a single 3’ x 7’ personnel door, and integrated ventilation louver and (2) ridge vents to allow proper air flow. A gland plate was also installed to seal the pipe entrance through the wall against weather. White splash trim and a drip shield over the door completed the installation package.

Measurement and Regulation Enclosure 7

Erected on a customer supplied skid in Oklahoma, this 8’W x 16’L x 10’H was constructed from Arctic White 24-gauge wall and roof panels with Roman Bronze double doors and roof trim. Another feature of this building included the gland plates, not yet installed in this photo, to seal the entry point of the pipes through the walls. Also seen in the photo near the eave of the building are the pipe vents for pressure relief of the housed equipment. This building was designed and constructed in full compliance with the applicable IBC codes.

Measurement and Regulation Enclosure 8

This interior view of a site constructed measurementation and regulation control building shows a typical look at Parkline’s interior liner system. This 14’ x 30’ x 10’H building was constructed on a tube frame to allow for placement on concrete runners surrounding the pipe installation and featured skylights to allow the entrance of natural lighting. In this photo, the horizontal supports and insulation can be seen awaiting the installation of the liner on either side of the double door opening. Additional features of this building included (2) 3’ x 7’ personnel doors, 24-gauge wall system, gutters and downspouts. The building was designed and constructed in accordance with all applicable IBC and IECC codes.

Switchgear Enclosure

Installed at a natural gas compressor station in Louden County, Virginia, this switchgear enclosure was constructed at our facilities in West Virginia and shipped to the jobsite as a fully integrated structure ready for placement and connection to onsite utilities. With final dimensions of 13’4”W x 24’L x 10’H, this 18 gauge galvanized building featured an S-style (shed) roof, bottom lift system, equipment doors for ease of access, a 3’ x 7’ personnel door, a 6’ x 7’ double equipment door with removable transom, floor cutouts for equipment cabling and the stairs and platforms on each side of the building. Parkline provided a full systems integration package by sourcing and installing the medium voltage switchgear, along with the lights, switches, receptacles, HVAC and a copper bus bar for equipment grounding needs. The building was designed and constructed in accordance with all IBC and IECC requirements for the installation location.

Utility Gas Building

This Utility Gas building was factory erected with an open base design and placed over a sump on a 12” concrete slab in Virginia. Constructed in accordance with all applicable IBC, IECC and NFPA codes, this building was also fully integrated to include electrical equipment rated for placement in the Class 1, Division 2 area. Featuring a 6’ x 7’ double door, this 12’W x 12’L x 9’H was manufactured utilizing our standard shell grey 24-gauge wall system with matching doors and trim. Additional features include the wall opening kit to allow for the ESD pressure vent, dual manual ventilation louvers and gutters and downspouts for rain water runoff.