Industry Specialties

Power Transmission

Collector Station 1

Due to the remoteness and the narrow roadways leading to the installation site in West Virginia, this Collector Station had to be constructed and integrated in our facilities and then shipped as a two-piece, split-design, top-lift building before being installed on the mountainside. The 20’W x 32’L x 11’H building included a 24 gauge interlocking wall panel system in Artic White, a 6’ x 7’ double door for equipment installation, one 3’ x 7’ personnel door and an exhaust louver for the battery back-up power system. Integration included the installation and testing of lights, switches, receptacles, control panels and marshalling cabinets. Parkline field services offloaded, reassembled and installed the building on the jobsite and connected the pad mounted back-up generator. This building was provided in compliance with all applicable IBC and IECC codes.

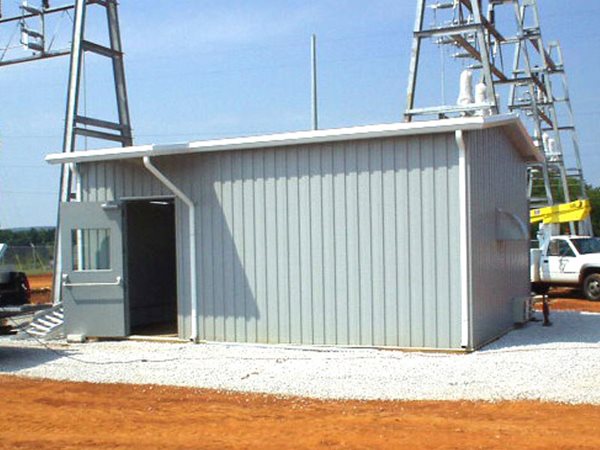

Collector Station 2

This site erected Substation Control house was purchase by a large utility company for a substation in Texas. An interesting feature of this 16’W x 24’L x 10’H 24-gauge structure is the extension of a 3’ wide section of the roof to provide a canopy over the doorway with an incorporated extension on the gutter and downspout system, rather than a separately installed bolt-on awning. Other key features included integration of the basic utilities (lights, receptacles and switches), the 3’ x 7’ personnel door with a 20” x 30” viewing window and a panic bar, the exhaust vent visible here on right wall of the building and the Shell Grey siliconized polyester coating applied to interlocking wall panels and both the interior and exterior of the door. This building was furnished in compliance with all applicable IBC and IECC codes.

Substation Control House 1

For this location in Alabama, our client needed a 12’W x 24’L x 10’H fully engineered, utility substation control house to house all the electronic protection and control panels required for operation of the substation. Once the design aspects were complete and materials were delivered to the jobsite, erection time at the site took less than 2 weeks for this 24 gauge, interlocking panel control house. This building features an “AL-Style” (or gable style) roof system with door awnings, an interior partition wall and a gutter & downspout system. Contracted erectors installed basic electrical utilities and installed HVAC systems at the site after erection of the building was completed. The client chose a Desert Tan color to reduce glare. This building was furnished in compliance all applicable IBC and IECC codes.

Substation Control House 2

This control house was constructed at our West Virginia facility for a utility company’s substation located in Ohio. Overall finished dimensions for this 18 gauge flat, interlocking panel building were 14’8”W x 40’L x 11.5’ Eave Height. Featuring an “S Style” or shed roof for water and snow runoff, this house featured a full systems integration package that included the installation, wiring and testing of the entire electronic protection system and control relay panels. The Control House was then loaded and shipped to the site. Other key features of this substation control house include a fire rated partition wall, single and double door systems a Desert Tan finish and various bulkheads for conduit penetrations. This building was furnished in compliance with all applicable IBC and IECC codes.

Substation Control House 3

This Substation Control House was designed for a utility client in Ohio for housing an array of marshalling panels. Final measurements were 13’4”W x 48’L x 11’H and some of the key features included our 24 gauge interlocking wall panel design with a Shell Gray exterior siliconized polyester coating, an interior 1-hour fire rated partition wall system, a bulkhead for cable tray connection to the interior of the building, multiple 3’ x 7’ doors with panic hardware and a curved exhaust vent to allow for heat dispersion for the battery system. Once construction was completed in our West Virginia facility, the building was shipped to the job site where a Parkline field services crew then offloaded and installed the building on the prepared foundation. This building was furnished in compliance with Ohio modular building state labeling requirements and all applicable IBC and IECC codes.

Substation Control House 4

This 32’W x 60’L x 11’H Control House was purchased as a Materials Only package that our client then self-erected at the job site. The 24-gauge building materials package included detailed erection drawings, all the materials and fasteners required to assemble the building and the insulation needed to combat the harsh Minneapolis, Minnesota winters. Additional features of the materials package and the finished structure included Pre-Painted panels in a Roman Bronze finish, a fully removable wall section that incorporated a 6’ x 7’ double door with a 2’ removable transom, a 3’ x 7’ personnel door with panic hardware and a viewing window, various wall opening kits, a gutter and downspout system that was color matches to the building and an engineer stamped drawing package for the overall design including the 70 lb snow load design needed on the AL-style (gable) roof system. This building was provided in compliance with all applicable IBC and IECC codes.

Substation Control House 5

Assembled and integrated with a basic utilities package in our West Virginia facilities, this 12’W x 20’L x 9’H Substation Control house was installed in the Texas hill country. The building was designed with a 24-gauge, Shell Grey, interlocking wall panel design with insulation to meet the applicable IEEC code, and included provisions for top lifting, an air intake louver, gutters and downspouts, an exhaust fan for the battery room, two 3’ x 7’ personnel doors and a cable riser between the two interior rooms. This building was constructed in compliance with all applicable IBC and IECC Codes, as well as in full compliance with the Texas industrial modular building state labeling program and all applicable IBC and IECC codes.

Substation Control House 6

Site constructed to serve as a storage building at a utility company’s substation in Pennsylvania, this 32’W x 40’L x 12’H featured 24 Gauge, Artic White interlocking panels with a 10’ x 10’ roll up door for easy access to stored equipment. A series of interior partition walls were used to create an incorporated office area with a 3’ x 7’ personnel door on the exterior. Once the gutter and downspouts were tied into the AL-Style gable roof by the Parkline arranged construction crew, the utility company had their own contract finish off the installation by installing the lights, switches and receptacles. This building was furnished in compliance with all applicable IBC and IECC codes.

Substation Control House 7

This factory erected, bottom-lift Substation Control house had the unusual feature of an interior chain link fence to allow the electric utility company to place equipment and personnel in one side and keep the other side for emergency services. Installed in Pennsylvania, the 12’W x 24’L x 10’6”H unit featured our Shell Gray, 24 gauge interlocking wall panel system with standard gutters & downspouts, a removable transom above the 6’ x 7’ double doors and one 3’ x 7’ personnel door on either side of the buildings to allow for separate entrances, a ventilation louver and a bulkhead for cable tray entrance. Before shipping the building to the site, Parkline’s integration team installed and tested control panels, an exhaust fan and the common electrical accessories including lights, receptacles and switches. This building was furnished in compliance with all applicable IBC and IECC codes.

SVC Enclosure 1

This 36’W x 80’L x 16’H SVC Enclosure was designed to serve as a single solution for multiple aspects of the application. The 24 gauge, interlocking panel building was site erected in Texas to better accommodate our client’s needs and avoid the cost freight expense of a pre-erected building. While one area of the building housed all the clients SVC equipment, the other area housed the electrical controls associated with the project. Some key design elements incorporated in this building were the “S-Style” (or shed style) roof design, partition walls and multiple interior and exterior doors, a full-size roll-up door and a Shell Grey exterior paint color. The integration of general utilities such as lights, receptacles, switches and panelboards along with the installation of the numerous HVAC systems to keep all the customer equipment at optimal operating temperatures. Door awnings, exterior lighting and a gutter & downspout system completed the exterior of this building. This building was furnished in compliance with all applicable IBC and IECC codes.

SVC Enclosure 2

Parkline arranged for the site erection and full electrical systems integration of this SVC Enclosure in North Carolina. The utility company that purchased this 16’W x 60’L x 12’H, 24 gauge fluted interlocking-panel building needed the finished structure to serve a dual purpose; one portion housed the control room for site operation while the other portion housed the SVC equipment that the client installed after construction of the building was completed. Some of the key features include an “AL Style” (gable) roof system, removable roof hatches, a 2-hour fire rated wall system installed as the common wall between the two rooms, multiple exterior single and double doors equipped with panic hardware, exterior lighting, an exhaust fan system, Parkline’s standard Shell Gray coating and a gutter & downspout system. This building was furnished in compliance with all applicable IBC and IECC codes.

SVC Enclosure 3

This large 35’W x 60’L x 16’H SVC Enclosure was erected at the client’s site in Maryland to eliminate costly transportation of a pre-erected structure. Once the materials arrived on site, total construction was completed in 4-5 weeks and included the incorporation of thyristor plates, three removable roof hatches and basic electrical utilities including lights, switches, receptacles and installation of the HVAC system required for maintaining safe operating temperature of the client’s equipment. This building was constructed utilizing Parkline’s Shell Gray, 24 gauge interlocking wall panel design with an “S Style” (or shed) roof and also included a gutter and downspout system for water and snow runoff. This building was furnished in accordance with all applicable IBC and IECC codes.

Switchgear Enclosure

This 14’8”W x 40’L x 10’H switchgear enclosure is an example of one of Parkline’s factory assembled buildings. This bottom-lift building included a full systems integration package. The building was assembled in our West Virginia facility and our systems integration team installed and tested basic utility systems, the HVAC systems and the OEM supplied medium voltage switchgear and its associated electrical equipment. The building was then secured, loaded and delivered to the site in Ohio as a completed unit. Application specific design aspects of this building included the construction and installation of equipment doors for client accessibility of the gear, 18 gauge interlocking panels with a Shell Gray siliconized polyester coating system and a pre-engineered bottom lifting system for loading and offloading. This building was furnished in compliance with Ohio’s modular building state labeling program and all applicable IBC and IECC codes