Modular Buildings

Marshalling Panel Building

10′ x 16′ Interlocking Galvanized Sheet Metal Marshalling Panel Building with Shed Roof, Single and Double Doors, Raised Flooring and Marshalling Cabinet

This marshalling panel building completed a major update of operational controls for a small utility plant in the Midwest. The marshalling panel cabinet, complete with sliding doors and sub-panels, was integrated into one side wall of the marshalling panel building. The building was also equipped with a single door, double door and raised (computer) flooring, with an open support frame in the center of the room to support the bottom entry into a set of vertical I/O module racks. As for this marshalling panel building, typical of about 50% of the structures we build, an integrator elected to install a climate control unit, electrical services, the I/O racks and marshalling cabinet wiring at their facilities, and utilized Parkline solely for the construction of the building’s shell and structural elements. As always, Parkline was extremely proud to supply this portion of the project to the integrator, who in this particular case easily completed the project at their facilities and then provided start-up assistance at the end user’s jobsite.

This Marshalling Panel Building provided critical functionality for a utility plant in Nebraska. From this view, the single side door and double end doors can be seen, along with the base mounted lifting lugs.

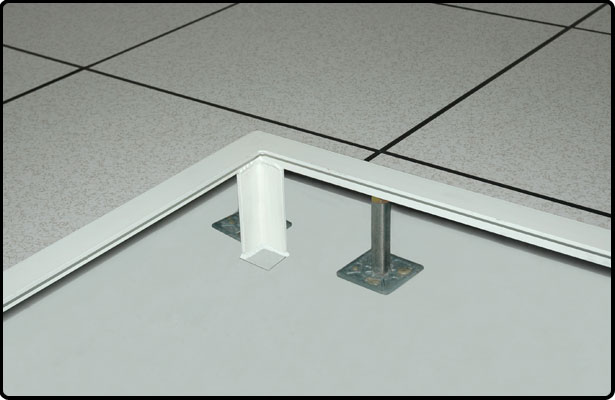

From the double door opening of this Marshalling Panel Building, a unique perspective just above the raised flooring illustrates how easily the integrator can begin installation of equipment immediately upon arrival.

Anticipating a significant weight load for the vertical I/O module racks, Parkline recommended the installation of an angle iron platform, flush to the top surface of the raised flooring system, to ensure adequate support.

In the closed position, this 12 inch deep Marshalling Panel Building’s cabinet doors form a barrier to protect personnel from accidental shock and adequately seal the thousands of terminations from dust and debris.

In this view, the oversized 8 foot tall double doors are shown open. These doors allow easy installation and service of the vertical I/O racks, but will most likely be sealed under normal operating conditions.