Stairs, ADA Ramps and Platforms

Large Wrap-Around Platform Unit

Stairways and 6 Foot High Elevated Platforms for Access to Modular Building’s Equipment and Personnel Doors

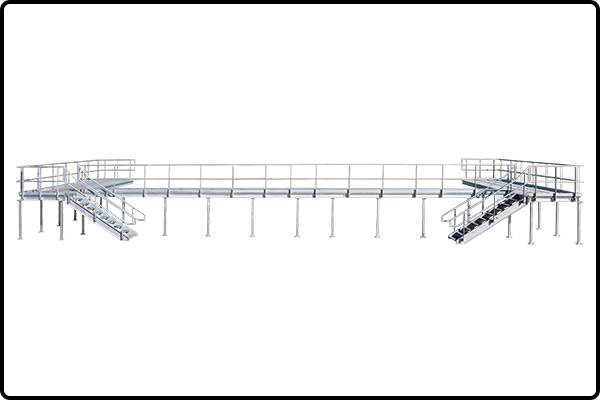

This massive Industrial Duty Stairs and Platforms Unit is one of three identical units that were manufactured for use with Parkline Industrial Duty Metal Shelters housing switchgear for mining site equipment in Arizona. This unit spans a distance of 42 feet in width and 26 feet in depth, with a wrap-around platform on three sides at an elevation of 6 feet. The dual stairways provide assent to the left and right side platforms, each built as one continuous assembly, and the front platform is divided into two sections that fit between the left and right side platforms.

The platforms of this Industrial Duty Stair and Platform Unit are 6 feet wide, providing comfortable access on three critical sides of the Switchgear Shelter. The left and right side platforms provide access to double doors on each end of the shelter used for equipment installation; while the front platform provides access to the main personnel entry door. The interior side of each platform of this wrap-around unit is fitted with brackets which, as shown in some assembly stage images above, provides a means of attaching the assembled unit to the shelter base.

As with all Parkline Industrial Duty Stair, ADA Ramp and Platform Units, all parts are manufactured as separate pieces which are all pre-drilled and pre-fitted prior to the application of a hot-dipped galvanized zinc finish. Pre-drilling extends to every aspect of construction, including mounting holes for the grating, which are retained by galvanized grating clips, through-bolted zinc-plated machine screws and zinc-plated nylon retainer nuts. The virtue of this minute detail ensures that all grating is firmly secured to this Industrial Duty Stairs and Platforms Unit, without compromising the hot-dip galvanizing process.

In fact, the only exception to this unique protection method is a very limited quantity of otherwise inaccessible welded nuts between certain platform members, which are clear-tapped after galvanizing to remove excess zinc plating. This extra step ensures easy insertion of critical platform assembly bolts by field assembly crews, and is a standard process on all products we produce.

This Industrial Duty Stairs and Platforms Unit demonstrates Parkline’s commitment to meeting any application. As our first major project, it allowed us to achieve an outstanding level of excellence. By benchmarking other products we’ve examined in the field over the last 40-plus years and considering our client’s perspective, we applied every conceivable insight to ensure absolute corrosion resistance and flawless assembly.

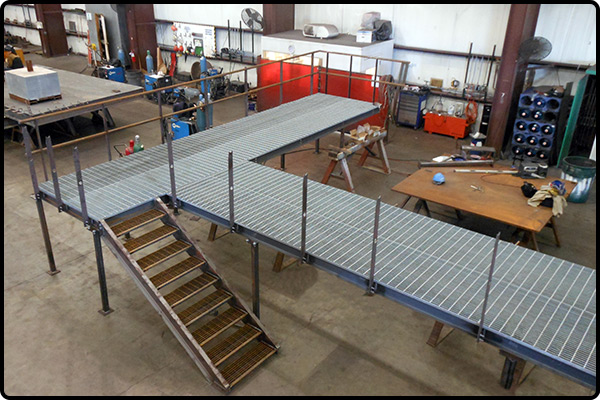

This view shows how we assembled each platform and attached them to their mated buildings, after the frames were welded. This was done to ensure exact alignment with mated brackets that were welded to the shelter as an extra measure of corrosion resistance. When purchased for existing structures, each unit is provided with legs or mating slotted bolt-on brackets that permit easy and precise field installation of all parts.

From this angle, you can see the side platforms extended fully across each side of the shelter. This is an option for our wrap-around platforms, which come in any length and width on any side. Providing variable widths, lengths and heights is another important feature that makes every Parkline Industrial Duty Stairs or ADA Ramp and Platform Unit the perfect solution to your needs. At Parkline, we work from uniform standards, not jigs.

Our standard process of complete pre-assembly is the next key step in production. As seen here, the stairs and support legs are already fitted, as the final section of platform grating is being cut to fit. All grating mounting holes are pre-drilled and slightly oversized to prevent any damage to their zinc coating during final installation of the grating. As clearly visible, the handrail uprights are also attached at this stage of production.

As the final step, prior to disassembly and transportation of the individual parts to a local hot-dip galvanizing facility, all handrail parts are fitted to their uprights and tacked securely in place before being removed for seal-welding at ground level. Again, as with all parts of any Parkline Industrial Duty Stairs or ADA Ramp and Platform Unit, this meticulous effort ensures absolute alignment for all parts of this custom-built product.

While not necessary under any other circumstances, this particular unit was reassembled by our team just prior to shipment, to validate all construction methods and attain valuable photographs for the purpose of sales and marketing. As we predicted at the onset of our design team meetings, assembly was an easy task for our crew, which reveled in the fact that each and every stage of our manufacturing process paid off in the end.

This final image is your call to action. Consider the elegance, beauty and precision of this finely crafted product that is engineered to meet your exact needs, regardless of any special circumstances or requirements. Understand by committing to purchase a Parkline Industrial Duty Stairs or ADA Ramp and Platform Unit, you’ll provide your organization with an exact solution to their needs. Call or send an inquiry now to get started!

Looking for a Quote?

Please send us some basic information and feel free to attach building specifications and other relevant documents. We’ll be in touch very soon.