Modular Buildings

Structural Base Options

Parkline manufactures an extensive array of structural bases for our complete line of modular buildings, industrial duty shelters and skid mounted process units. We also provide structural bases with numerous lifting and cinching or tie-down provisions to ensure they’re fully secured during transportation and can be easily offloaded when they arrive at your facility.

Please take a moment to review the various options we provide by clicking any image below and learning more. At Parkline, it’s all about providing you with exactly what you need to meet your unique application.

Base Styles

Parkline Structural Bases are manufactured from US made and fully traceable steel, they are welded with extreme precision by our team of AWS certified welders. They are then finished to the highest applicable standards, under continuous quality assurance examinations, utilizing our in-house bead blasting and coating applications equipment. Best of all, because all manufacturing processes are performed within our massive 110,000 square foot manufacturing facility, Parkline can produce these products to the same immaculate standards, year-round, regardless of any inclement weather conditions! Click any image below to learn more!

Decked Bases

Parkline Decked Bases are specified for about 70% of our modular building and shelter products, and as seen in this dramatic underside view, they feature a ladder style frame with a solid plate deck. The frame consists of major perimeter and minor cross-member interior beams along with lifting point cross-member beams that are typically sized to match the perimeter beams. We manufacture deck bases from 4 square feet to massive 30 feet wide and 80 feet long sizes. Perimeters beams can exceed 24” H Beam, and these bases can support weights exceeding 500,000 pounds! Decked Bases can be constructed from any form of metal, and can feature insulation, underside liners and mastic coatings. They can also be produced with split-level, recessed or elevated sections for above or below deck cable tray, raised (computer) flooring systems and other amenities.

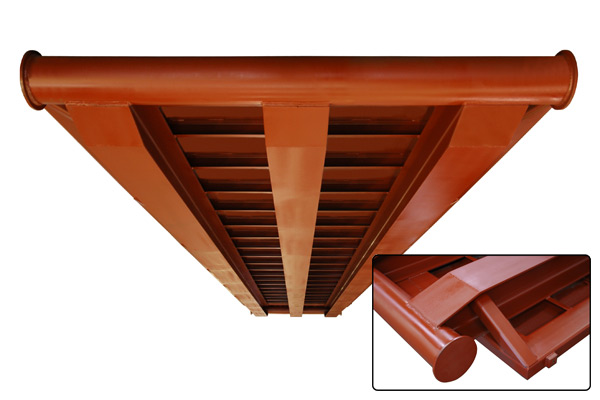

Drag-Skid Bases

Parkline Drag-Skid Bases are extremely robust and used primarily for processing equipment, vessels and tanks or SCR, DCS, MCC, generator, turbine, mud-logging and switchgear buildings in the oilfield. They’re specifically designed for frequent transport by tilt-bed trailers, feature wide flange H-Beams modified with “upturned” ends and drag-skid bars formed from schedule 80 pipe and oversized end caps. Drag-Skid Bases typically feature a third major beam running the full length of the base and extremely recessed cross members (as shown in this image) to increase rigidity, provide the greatest area of ground surface contact and minimize underside mud accumulation during loading and unloading. Need help? Parkline manufactures these incredibly durable bases frequently, and can provide very valuable insights about best design practices on request!

Open Bases

Parkline Open Bases are a very popular alternative to decked bases, when a client intends to set a building on a concrete pad or footings, and does not require a deck. They features perimeter frame members only, along with seal-welded gussets in each corner. As shown in this underside image, they can also feature one or more recessed doorway thresholds in permanent step-over or removable configurations to comply with ADA access requirements. Consider the use of Parkline open bases for any modular building or shelter intended for a utility or low occupancy application, such as storage, analytics, or metering. Have no fear regarding the integrity of open bases, whether you’re considering single or double-wide (split) modular building or shelter configurations – as required, Parkline adds removable cross-braces to keep all walls stable during transportation and offloading.

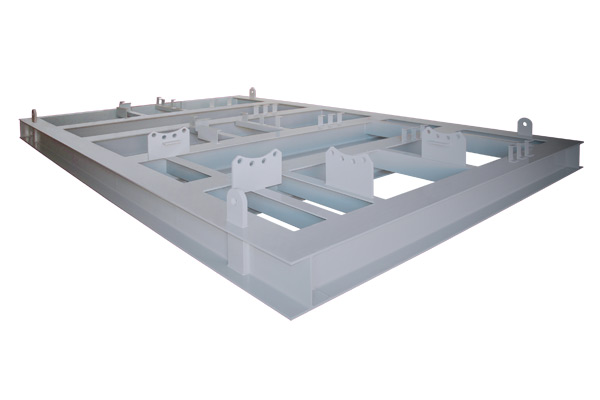

Equipment Bases

Parkline Equipment Bases are most commonly used as process unit skids, to support piping, vessels and other processing equipment. In today’s world of modular solutions, Parkline can provide any size or shape of equipment base to get your project off the ground! As shown in this image, this equipment base features an I-Beam perimeter and various I-Beam cross members strategically located to support the massive weight loads of the process equipment. In addition, custom support brackets and risers were added to mount the pipes, instruments, vessels and other process equipment. These bases can also accommodate surface mounted or recessed grating, decking and modular buildings or shelters, large control panels, compressors or generators. Think of us for your next equipment skid project – after all, we know a thing or two about pipes and vessels, too!

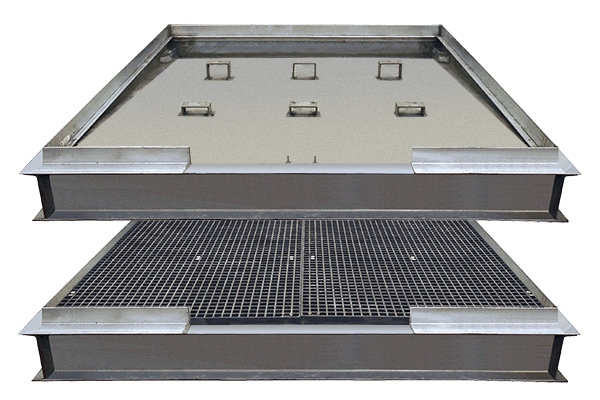

Sump Bases

Parkline Sump Bases provide chemical spill containment basins within their structural cavity. Depending on the likelihood, frequency, quantity and volatility of potential spills, basins can be flat, which will rely upon evaporation or manual spill recovery efforts, or they can sloped in single or multiple directions to channel chemical spills toward one or more collection points fitted with drain connections. As shown in this “before and after” image of a very basic sump base, the basin is sloped to the rear to a drain connection, and features riser brackets, that along with flanges on all sides of the base support the grating deck. Flat or Sloped spill containment basins can also be located within any section or portion of a decked base, for example under a metering pipe, chemical pump or other device that has a leak potential. Rest assured we handle chemical spills with ease!

Extended Bases

As the name implies, Parkline Extended Bases reach beyond the perimeters of a modular building and shelter walls to support ancillary equipment or provide critical storage or work space. Most often, these extensions are only a few feet in depth on one end of a structure, and are used to support massive HVAC equipment for switchgear, MCC, VFD or RIE buildings. However, as shown in this image, extended bases may be expansive, extend beyond just one side of a modular building or shelter and feature recessed grating, equipment mounting pads (in this case a micro-turbine power generator) and safety rails. Other applications include microwave, doppler and missile tracking radars, windmill stanchions, and multiple micro-turbines for self-powered remote drilling rigs. Regardless of your application, consider extended bases as an ultimate means to getting it all!

Modular Building, Shelter Lifting and Cinching Options

Parkline provides a wide array of solutions to meet your exact requirements for modular building and shelter loading, off-loading and transportation. From base mounted lugs and lift extensions, to drag bars, cinch tabs and forklift pockets, Parkline can equip your modular building or shelter for safe and secure handling in every situation, no matter how difficult or easy the task may be at your jobsite. Parkline can also equip the largest modular buildings and shelters we manufacture with top-lift lugs, so that the entire wall and roof system or the roof itself may be removed for access to critical items such as pumps, turbines, motors or generators. Simply stated, we can accommodate any need for any application, regardless of how far, how high or how often you must move your modular building or shelter!

Shackle Points

As our most economical option for securing your modular building or shelter to a trailer during transportation, Parkline Shackle Points reduce shipping width and permit easy tie-down with load binders or ratchet straps, to secure modular buildings and shelters during transportation. As shown here, shackle points are holes placed into the exposed web flange at the ends of modular building or shelter bases. While not intended as nor suitable for use as lifting point connections, Parkline Shackle Points are more than adequate if your field crew has the means to off-load and positioning your modular building or shelter with forklifts or a tilt-bed trailer. They also serve as the best and most practical transportation tie-down points if your modular building or shelter is equipped with Top-Lift Lugs.

Lift Extensions

Parkline Lift Extensions permit the economical crane offloading of small or lightweight modular buildings and shelters, with the same certified integrity of lifting lugs we recommend for larger or higher weight modular buildings and shelters. These lifting extensions are usually formed from channel iron and can be extended laterally as required to provide a clear lifting point beyond wall mounted equipment such as air conditioning units. In some instances, depending on the length required, these lifting extensions may also feature reinforcement gusset brackets to prevent deformation during loading and off-loading. Select Parkline Lift Extensions for smaller modular buildings and shelters when cranes will be preferred to set your modular building or shelter in its final location.

Forklift Pockets

As shown here, along with lift extensions on a fiberglass shelter, Parkline Forklift Pockets provide a convenient means for loading, unloading and moving small, lightweight modular buildings and shelters from jobsite to jobsite, and are often utilized for mud-logging, temporary metering, seismology and portable laboratory buildings. Forklift Pockets are formed from 2 by 4 or 3 by 6 inch rectangular seam welded structural tubing that typically extends through both sides of the structural base. The tubing is seal welded at all points of perimeter and cross-member beam intersection and coated in the same manner as all other structural members of a modular building or shelter base, to achieve maximum strength and corrosion resistance. Consider this option if frequent relocation and safe off-loading of your modular building or shelter with forklifts is essential.

Drag Skid Bars

Drag Skid Bars allow your modular building, shelter or equipment base to be transported and off-loaded from tilt-bed trailers. They also permit your modular building, shelter or equipment base to be towed across stable areas when relocation of the modular building, shelter or equipment base is anticipated to occur on a frequent basis. As shown in this example, this Parkline Drag Bar is accompanied by Lifting and Loading Tabs, to permit the use of either looped or shackled cables. Read more about Equipment and Drag-Skid Bases above for more information, and choose Parkline Drag Bars for modular building, shelter or equipment bases if frequent transportation or oilfield deployment is required. Typical applications include chemical processing, mud-logging, temporary metering, seismology and portable labs.

Top Lifting Eyes

Parkline Top Lifting Eyes are a unique option located at the top of a modular building or shelter, which are connected to the base by means of structural components concealed within the walls. Lifting integrity is assured since the structural components transfer the lifting load from these top lift eyes to the structural base. This lifting option is often critical when mounted equipment would interfere with a traditional bottom lifting option and simplifies installation when require an open base is required so that a modular building may be positioned over existing items such as pumps, turbines, motors or generators. Lifting eyes and structural components are sized based on the total load to be lifted and have been pre-engineered to meet a variety of load capacities.

Cinch Tabs

When your modular building or shelter is relatively small and can be conveniently off-loaded and positioned on the job-site with forklifts, or you can access the final installation site with a tilt-bed trailer, consider the use of Parkline Cinch Tabs. These welded extensions are formed from thick plate steel and seal-welded to the lateral ends of structural bases to form an incredibly strong point of connection. They therefore serve as excellent tie-down points during trailer transportation and will also permit direct line towing of a modular building or shelter into a final position at the jobsite. However, since there engineered strength is intended to withstand lateral forces only, Parkline Cinch Tabs are not intended for or suitable to serve as lifting points.

Looking for a Quote?

Please send us some basic information and feel free to attach building specifications and other relevant documents. We’ll be in touch very soon.